BENEFITS

stock.adobe.com

Safe filtration in chemical production

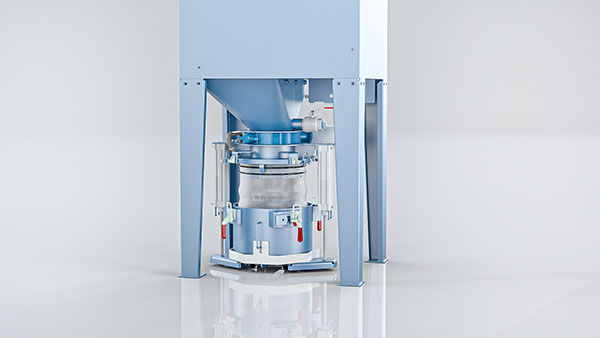

Highly efficient filtration technologies are essential in chemical production processes in which bulk materials, powders or other particulate educts or products play a role. If filter systems are integrated into the process, aspects such as contamination-free recovery, chemical resistance and easy cleanability are of primary importance, in addition to high separation performance.

Herding® filter systems meet the highest requirements in terms of contamination-free operation, durability and safe handling. Even the finest particle fractions are reliably separated on the basis of pure surface filtration. Lowest clean gas values, absolutely constant operating conditions, highest availability and energy efficiency are the key features of the innovative technology.

Durable

Long service life

Constant operating conditions

Energy efficiency due to low cleaning pressure

Pure air and clean gas due to lowest clean gas values

Resistant to chemicals

Compact design

Operational safety due to rigid filter matrix

Pure recovery through fiber-free filter medium

PROCESSES

stock.adobe.com

Sustainable filtration for all areas

Often even the smallest product contaminants are the reason for rejecting complete production batches with high losses. In addition even slightest contamination in the ambient air of production facilities can cause harmful effects on the health of employees. The motivation for sustainable and efficient filtration therefore has many backgrounds in chemical production. Pure product recovery, easy and complete cleaning possibilities as well as maximumb separation performance are essential quality requirements for filter systems in chemical manufacturing processes. Herding® filter technology allows for maximum availability and safe plant operation in almost all processes that generate particulate emissions.

Production processes

- Milling

- Drying

- Conveying

- Granulating

- Bagging / Packing

- Screening / Classifying / Sifting

- Dosing / Weighing

- Mixing / Blending

- Silo venting

- Working place extraction

SYSTEMS

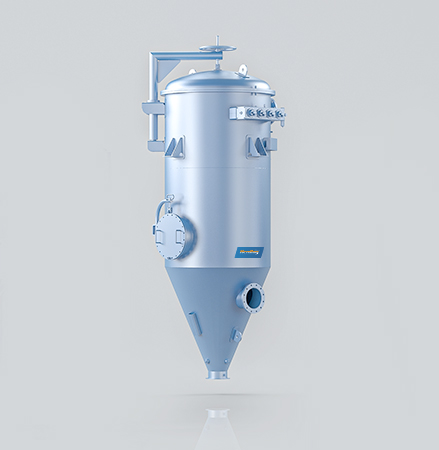

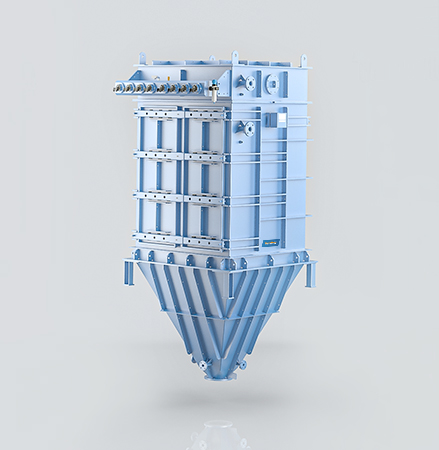

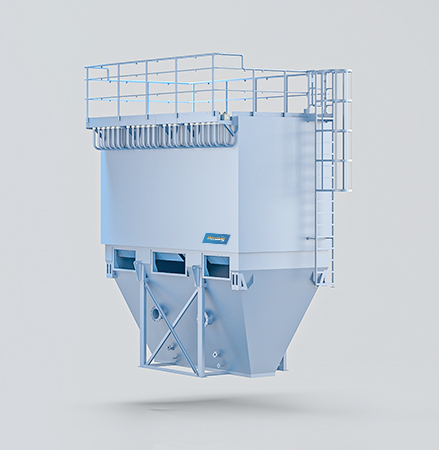

Herding Filtertechnik – pure productivity

Sustainable Filtration – „made in Germany“

From filter media to completely installed filter systems, the production chain starts with the manufacturing of the flter media and ends in the final assembly. The vertical range of manufacture ensures an extremely high quality standard and the greatest possible flexibility for customers worldwide.

Based on a well-planned modular construction system, a wide range of plant type series can be realized, individually customized to suit the specific applications and various demands of the chemical industry. A large variety of housing and construction materials rounds off a broad range of use in the chemical production.

EXPLOSION PROTECTION

Explosion protection on filter systems

Explosion protection on filter systems

The composition, particle size distribution and specific explosion characteristics of the various particulate materials in chemical production often require a protection concept tailored to the application due to the resulting explosion hazard.

Herding® Filtertechnik provides the user with a wide-ranging portfolio of preventive and constructive safety technology for filter systems. From consulting and selection of the suitable protection concept to the safe and ATEX-compliant design of the filter systems up to their installation, commissioning and maintenance.

The Herding Sinter-Plate Filter offers a unique advantage: It is the only filter element on the market whose rigid body acts as a DustEXZoneBarrier, which means that there is no dust-explosive atmosphere on the clean gas side of the filter system.

Explosion protection concepts

Preventive, primary measures

Avoiding explosive atmospheres by separating processes into sections with and without organic solvents.

Preventive, secondary measures

Avoiding effective ignition sources in filter systems. In many applications, preventive measures are sufficient to safely avoid explosions in the filter system.

Constructive, tertiary measures

Reducing the effect of the explosion event in the filter system

- Explosion-proof design – Herding RESIST

- Raw-gas side pressure relief, e.g. with explosion panel

- Raw-gas side flameless pressure relief with suitable quenching devices

- Clean-gas side flameless and smoke-free pressure relief – Herding FLAMELESS

- Explosion suppression

Herding FLAMELESS

Option of constructive, tertiary measures: Clean-gas side, flameless and smoke-free pressure relief

Chemical processing

OPTIONS

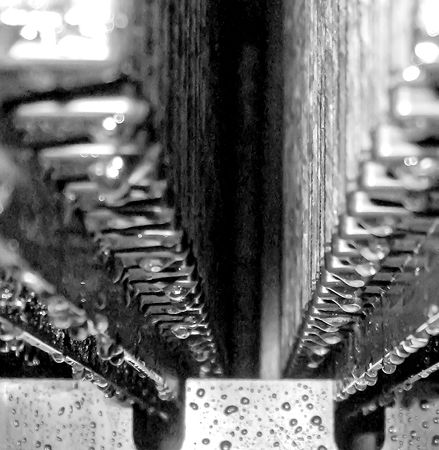

Surface treatment

- Avoiding of deposits on components in contact with the product, e.g. by polishing or grinding

- Wear protection against mechanical or chemical attack, e.g. by hard facing layers, special coatings

Dust discharge

- Continuous or discontinuous systems, tailored to application and customer requirements

- Examples: Rotary air locks, valves, screw conveyors, etc.

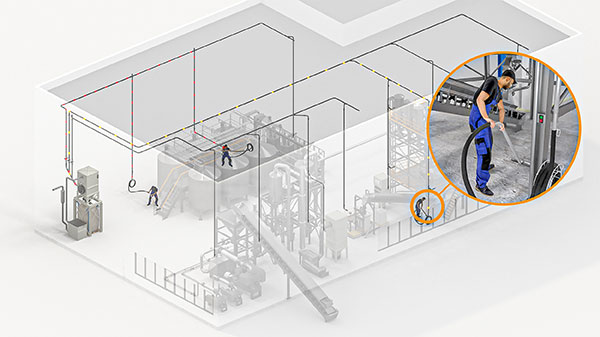

Vacuum systems

- Central disposal of separated dusts in one filter unit

- Central vacuum cleaning systems

Dust collection and duct work

- Engineering, delivery and installation

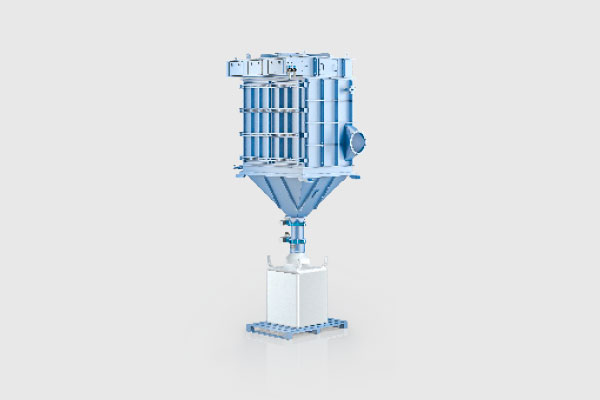

Containment

- Secondary filter, optional with Bag-In / Bag-Out

- Herding FIRST RINSE for contamination-free exchange of the Herding Sinter-Plate Filters

- Herding SAFE CHANGE for safe dust discharge and disposal at the interface with highest frequency for the operator. Herding SAFE CHANGE with Bag-In/Bag-Out has been proven to meet high OEB standards

Herding MULTICOATER

- Additive for handling sticky dusts

- Passivation to minimize the risk of fire and explosion of the dusts

Control

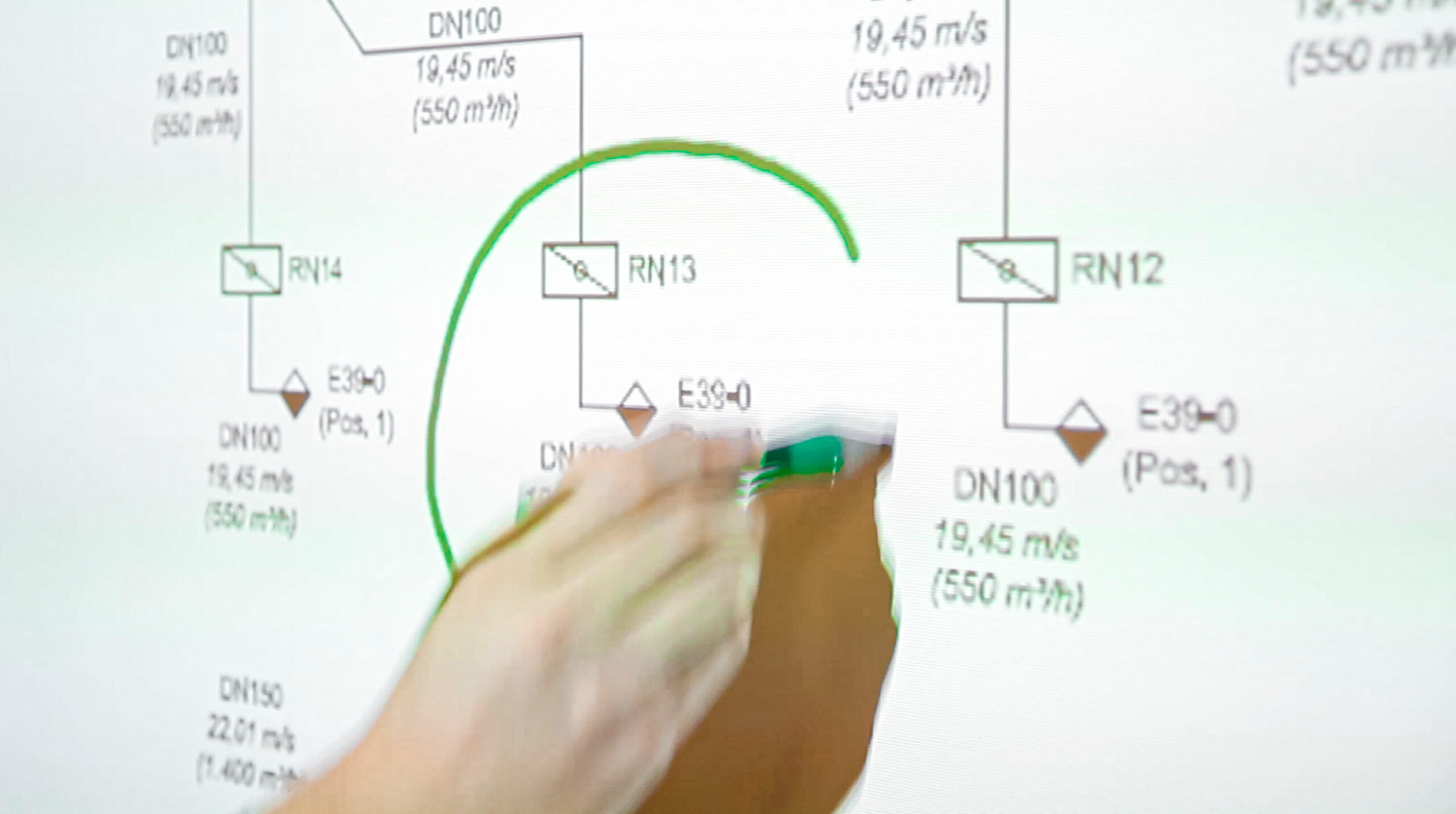

Herding CONTROL HC 4.0 specifically adapted to the needs of filter technology PLC for more complex system solutions

Insulation / Heating

To avoid condensation in the filter system

Cleaning

WIP devices